Delta 250 Trailer Manual

Delta 250 Trailer Manual

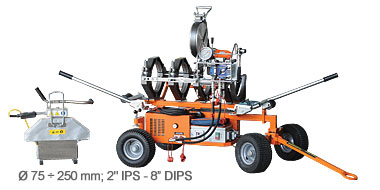

DELTA 250 TRAILER MANUAL: self-aligning hydraulic butt fusion machine, suitable for welding underpressure pipes for water, gas and other fluids up to Ø 250 mm (8" DIPS). Welds according to the International standards ISO 21307 HIGH PRESSURE / ASTM F2620.

DELTA 250 TRAILER MANUAL is able to weld fittings like elbows, tees, Y-branches and flanges necks. Available in the 110 V and 230 V versions. Includes:

- A trailer-mounted machine body, easily removable from the trolley

-...

delta 250 trailer

delta 250 trailer

DELTA 250 TRAILER: self-aligning hydraulic butt fusion machine, suitable for welding underpressure pipes for water, gas and other fluids up to Ø 250 mm (8" DIPS). Built according to the International standards ISO 21307 HIGH PRESSURE.

DELTA 250 TRAILER is able to weld fittings like elbows, tees, Y-branches and flanges necks. Available in the 110 V and 230 V versions. Includes:

- A trailer-mounted machine body, easily removable from the trolley

- Fast-locking adapters system SMARTLocK...

REMEDY 355

REMEDY 355

SMALL DIAMETERS FUSION

REMEDY 355 is an independent, high-productivity welding machine driven by tracks and powered by a Diesel on-board generator. Designed for butt

welding HDPE and PP pipes from Ø 125 to 355 mm (from 4” to 14” IPS; from 4” to 12” DIPS). Suitable for ISO 21307 High Pressure and ASTM F2620 fusion standards.

Versatile

- Working range

from Ø 125 to 355 mm

from Ø 4” to 14”IPS

from Ø 4” to 12” DIPS

- Materials: HDPE, PP

- Manual...

delta 355 trailer

delta 355 trailer

DELTA 355 TRAILER welds HDPE, PP pipes and fittings for the transportation of gas, water and other fluids under pressure from 125 mm to 355 mm or from 4” IPS to 14” IPS. It is designed to work according to welding standard ISO 21307 High Pressure.

Machine composition:

- Removable control panel with data-logging, memory up to 4000 welding reports, GPS treacebility; USB port for welding report / data download / firmware upgrade. Easy-life welding control system: hardware and...

delta 500 trailer

delta 500 trailer

DELTA 500 TRAILER is a self-aligning fusion machine, suitable for welding thermoplastic pipes for the transport of water, gas and other fluids under pressure, up to Ø 500 mm.

Machine can fuse pipe according to the ISO 21307 High Pressure standard.

Standard machine features:

- Machine body mounted on a 4 wheeled chassis, easily removable for working in tight spaces

- New RITMO Patented assisted system to open/close/lift clamps-heater-facer

- Machine body with an automatic heating...

delta 500 all terrain

delta 500 all terrain

DELTA 500 ALL TERRAIN is powered by a low-vibration diesel engine and equipped with front steering wheels and rear traction. The machine is suitable for welding pressure pipes (HDPE, PP) for the transportation of water, gas and other fluids up to Ø 500 mm (20 "IPS).

Built according to the International standards ISO 21307 HIGH PRESSURE.

- Working range from Ø 200 to 500 mm (6" IPS ÷ 20" IPS)

- Welds fittings like elbows, tees, Y-branches and stub flanges

- New RITMO assisted system...

REMEDY 500

REMEDY 500

REMEDY 500 is an independent, high-productivity welding machine driven by tracks and powered by a Diesel on-board generator. Designed for butt welding HDPE and PP pipes from Ø 200 to 500 mm (from 6” to 20” IPS; from 6” to 18” DIPS). Suitable for ISO 21307 High Pressure and ASTM F2620 fusion standards.

Versatile

- Working range

from Ø 200 to 500 mm

from Ø 6” to 20”IPS

from Ø 6” to 18” DIPS

- Materials: HDPE, PP

- Manual controls

- Tracked welding machine

-...

REMEDY 500 FA

REMEDY 500 FA

REMEDY 500 FA is an on-site welding machine equipped with a low-vibration diesel engine and tracks. The machine is suitable for welding pressure pipes (HDPE, PP) for the transportation of water, gas and other fluids up to Ø 500 mm. Built according to International Standards.

- Working range from Ø 250 to 500 mm

- CNC welding control system: hardware and software have been developed to interact to each other sharing data during the entire workflow. Once set the welding parameters up,...

delta 630 trailer

delta 630 trailer

DELTA 630 TRAILER is a self-aligning fusion machine, suitable for welding thermoplastic pipes for the transport of water, gas and other fluids under pressure, up to Ø 630 mm ( 24" DIPS)

DELTA 630 TRAILER allows to easily weld fittings like elbows, tees, Y-branches and stub flanges

Machine can fuse pipe according to the ISO 21307 High Pressure standard.

Standard machine features:

- Machine body mounted on a 4 wheeled chassis, easily removable for working in tight spaces; steel...

delta 630 all terrain

delta 630 all terrain

DELTA 630 ALL TERRAIN is the Pipe and Fittings FUSION Machine designed to face the toughest working conditions.

DELTA 630 ALL TERRAIN wants to mark a turning point to the world of Field Fusion. It stands out for being extremely easy to set up and work with. Take the heating plate and facer disconnecting system for example; the positioning / removal of the pipes is made without obstacles, giving the operator more time for what really matters.

Italian design, known for paying particular...

delta 1000 trailer

delta 1000 trailer

DELTA 1000 TRAILER is a self-aligning fusion machine, suitable for welding thermoplastic pipes for the transport of water, gas and other fluids under pressure, up to Ø 1000 mm ( 36" IPS/DIPS).

Machine can fuse pipes according to the ISO 21307 High Pressure standard.

Standard machine features:

- Machine body mounted on a 4 wheeled chassis, easily removable for working in tight spaces; steel hydraulic clamping with the fast-locking inserts, which allows to place and remove inserts in...

REMEDY 1000 EL

REMEDY 1000 EL

REMEDY 1000 EL is an independent, high-productivity welding machine driven by tracks and powered by a Diesel 3.6-cylinder in-line Turbo-Common Rail on-board generator. The machine designed for butt-welding HDPE and PP pipes up to Ø 1000 mm for the transportation of water, gas and other fluids under pressure. The machine can weld according to ISO 21307 High Pressure and ASTM F2620 standards.

- Working range from Ø 355 to 1000 mm

- EASY LIFE welding system that allows the operator to...

HS ROLLERS

HS ROLLERS

ROLLER HS, this device is essential for supporting the pipes while they are being welded with the butt fusion machines. The rollers minimise pipe friction and drag force no matter which is the construction site condition.

Special design for ALL TERRAIN and TRAILER LINE.

- HS ROLLER 250 which can sustain pipes up to Ø 250 mm 8" IPS

- HS ROLLER 355 with a working range up to Ø 355 mm 14” IPS

- HS ROLLER 630 with a working range up to Ø 630 mm 24” DIPS

- HS ROLLER 1000 with...