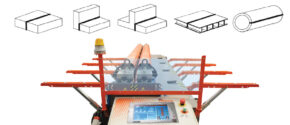

POLYFUSION 3 Pneumatic sheet welding machine

CNC welding cycle

Compliant with welding standards DVS 2207

PE (DVS 2207-1); PP (DVS 2207-11); PVC-U (DVS 2207-12); PVC-C (DVS2207-13); PVDF (DVS 2207-15)

Weldable materials: sheet in PVC, PE, PP, PVDF; twin walls in PE and PP.

Welding range 3 ÷ 50 mm (contact RITMO S.P.A for more details) solid wall; max 60 mm twin walls

VERSATILE

- Welds up to 3 mt length

- Suitable for small size sheets welding

- Working pressures: nominal 7 bar - maximum 9,5 bar

- Type of butt fusion welding: Straight, 90 ° welding (accessory on request), T welding (accessory on request), Circular welding (accessory on request)

PRECISE

- High density locking clamps that provide an homogeneous pressure distribution

- Led lights throughthe entire welding area

- Graduated scales to set the sheet in position

- Constant stabilizing pressure control

- Additional overboost

- Unlimited store of welding report

- Unlimited store of pre-setting parameters and possibility to recall them

- Welding cycles management according to the standards or customizable

Pre-set welding standards: - PE (DVS 2207-1) - PP (DVS 2207-11) - PVC-U (DVS 2207-12) - PVC-C (DVS2207-13) - PVDF (DVS 2207-15)

Twin wall pre-set parameters on suggested values: PANELTIM - RÖCHLING - SIMONA

COMPLETE

- 4 independent welding areas

- CNC welding cycle

- Pre-setting store and recall parameters

- PLC control panel

- 12” touch screen

- Remote control and analysis

- Diagnostic feature

- Upgradable Software via USB

Standard composition:

- Folding lateral supports with bearing balls for the easy sheet movements

- High density locking clamps: they provide an homogeneous pressure distribution capable of stopping both large and thin thicknesses sheets, and working with long or short sheets

- Led lights through the entire welding area

- New Ritmo “AirPlus” system allows to complete a welding cycle even in the event of a unexpected fault of the air supply in your building

- The “Adjusty” system automatically adjusts the distance between heating plate and machine edge according to the thickness of the sheets. With thin sheets the system permits a welding without overlapping while for thick sheets enough space for the bead is guaranteed

- A PLC control panel allows the operator to program the working cycle quickly with the help of an intuitive touch screen

- Internal memory for unlimited number of jwelds.

- Download report in CSV format

- USB port

- Unlimited welding pre-setting (customized or preferred) easy to be recalled.

- Wide range of optionals and accessories to expand its functionality

Technical features

| Materials |

PE/PP/PVC-C, PVC-U, PVDF |

|

Max.working width

|

3050 mm |

|

Weldable thickness solid wall

|

3 ÷ 50 mm (contact Ritmo S.P.A. for details) |

|

Weldable thickness twin walll

|

up to 60 mm |

| Types of welding |

Plane, 90°, T, Circular |

| Power supply |

400 V |

| Max. absorbed power |

11500 W |

| Minimum requirements pneumatic supply |

7 bar capacity= 300 l/min |

| Memory |

limitless |

| Report |

CSV limitless |

| Pre-set welding standards |

yes |

| Weight |

2550 Kg |

| Dimensions unfolded bracket |

4307 x 2673 x 1508 mm |